Last week, I had the opportunity to tour several of the W.L. Gore & Associates facilities that produce the company’s venerable Gore-Tex® brand of breathable, waterproof fabric. If you didn’t know that Gore-Tex was a brand and not a company, don’t feel bad – I didn’t know, either, until a few days before my trip when someone at work mentioned that they used to use Gore cables in their radar systems. Gore cables? Turns out, Gore is into a lot of interesting areas, from emerging energy to medicine.

Last week, I had the opportunity to tour several of the W.L. Gore & Associates facilities that produce the company’s venerable Gore-Tex® brand of breathable, waterproof fabric. If you didn’t know that Gore-Tex was a brand and not a company, don’t feel bad – I didn’t know, either, until a few days before my trip when someone at work mentioned that they used to use Gore cables in their radar systems. Gore cables? Turns out, Gore is into a lot of interesting areas, from emerging energy to medicine.

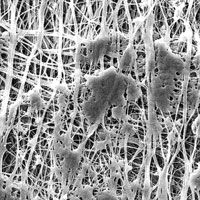

Cross section microphotograph of an EPTFE membrane showing the small voids that allow vapor to pass, similar to steel wool at a microscopic scale

W.L. Gore & Associates began in 1958 when Wilbert L. “Bill” Gore left DuPont to start his own company, with his wife Genevieve and explore other uses for polytetrafluoroethylene (PTFE). Although PTFE is not exactly a household word, DuPont’s brand name for it is – Teflon®. The big breakthrough, for us outdoor enthusiasts, came in 1969 when the couple’s oldest sone, Bob, discovered that when a sheet of PTFE was stretched it could be formed into membranes to make unique breathable and waterproof fabrics. This Expanded PTFE, or EPTFE, is the basis for the company’s Gore-Tex fabric that we are all so familiar with today.

Steve Romeo, from TetonAT.com, plunges his EPTFE-wrapped wet hand into a bucket of ice water and it comes out completely dry

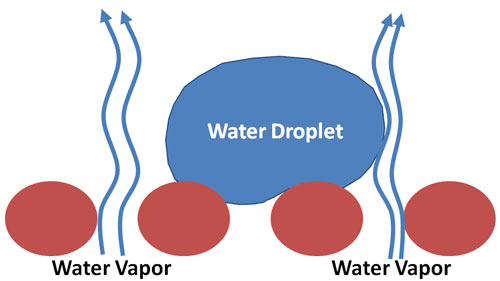

It’s a bit difficult to grasp the breathable-and-waterproof concept from a microphotograph, so I put together a simple diagram to demonstrate the idea. Surface tension holds the droplet of water together and, as a droplet, the water is much too large to pass through the voids in EPTFE. Water vapor from your body, however, can pass right through those tiny voids in the membrane. Another important factor in the performance of EPTFE is your body, itself. Provided you are not wearing Gore-Tex in the jungle, and it seems an unlikely environment for the technology, the water vapor coming off your body is much warmer than the outside air. The law of conduction, or Fourier’s law, states that thermal transfer always occurs from a region of higher temperature to a region of lower temperature – in essence, that hot water vapor from your body literally flies out of your jacket (for example) and into the colder air that it seeks.

Sample of Gore-Tex Product Testing from Roy Scribner on Vimeo.

With the science out of the way, we moved on to the extensive in-house testing capabilities that Gore uses to certify and validate that products meet their licensing standards. Probably the room that impressed me most, and one that I highlight in the video, was the washer room. I could not fit the scale of the room into the picture frame, but there are rows and rows of washing machines that are all churning away on garment samples. If you ever worried about damaging your Gore-Tex gear by machine-washing it, you can put that worry to rest. In fact, the Gore-Tex folks actually recommend regular machine washing and drying to keep the fabrics waterproofing ability working.

With the science out of the way, we moved on to the extensive in-house testing capabilities that Gore uses to certify and validate that products meet their licensing standards. Probably the room that impressed me most, and one that I highlight in the video, was the washer room. I could not fit the scale of the room into the picture frame, but there are rows and rows of washing machines that are all churning away on garment samples. If you ever worried about damaging your Gore-Tex gear by machine-washing it, you can put that worry to rest. In fact, the Gore-Tex folks actually recommend regular machine washing and drying to keep the fabrics waterproofing ability working.

They explained that the outside of the material is comprised of microscopic vertical protrusions, like hairs, that hold water droplets off the surface of the material. This keeps the material from becoming waterlogged and inhibiting its ability to breath. As these “hairs” become dirty, they flatten and lose their ability to keep water off the surface of the material. Washing the garment cleans them, of course, but machine drying helps restore them to their original shape and is actually beneficial.

Jake Mohrmann (MountainTechs.com) and Eileen Ringwald (Rockgrrl.com) checkout glove construction

I really learned a lot about product testing and the performance of Gore-Tex fabric, at the Gore facilities. I’m used to thermal chambers and vibration tables from my work in the aerospace industry, but to see that kind of testing performed on textile products really surprised me because I know how expensive it is. I was also impressed by the way that Gore simulated real-world conditions as much as possible. I’ve seen some big thermal chambers, but I’ve never seen one big enough for people to stand and move around in – and Gore’s will easily hold half-a-dozen people. This is the kind of commitment to testing and quality assurance is not something that is cheap or easy to do.

See also…

Pingback: Tweets that mention The Gore-Tex Experience -- Topsy.com

Wow! I never knew how Gore-Tex worked. All these years of wearing jackets and boots made with the material and I never grasp how it kept me dry. Thanks for the explanation!

Thanks, Robert – I must admit that I, too, did not have a grasp on the whole “waterproof but breathable” concept until they explained it (several times).

WOW!

Great post Scrib’!

I think I can get college level science credit just for reading it!

Thanks, Ken – I remember a few times in the backwoods of North Carolina where I sure wish we would have had some Gore-Tex. Somehow, it never caught up with me – even in the Oregon NG, they didn’t get it until after I got out in 2000.

Pingback: Gore-Tex advertising enters 21st century